Welcome to visit Fugui International Trade (jinan) Co., Ltd.website !

In order to produce high-precision plastic products, injection molding machines are moving towards electrification. Electric injection molding machines are more environmentally friendly and energy-efficient than conventional hydraulic injection molding machines, and their demand has been increasing in today's environmentally conscious era.

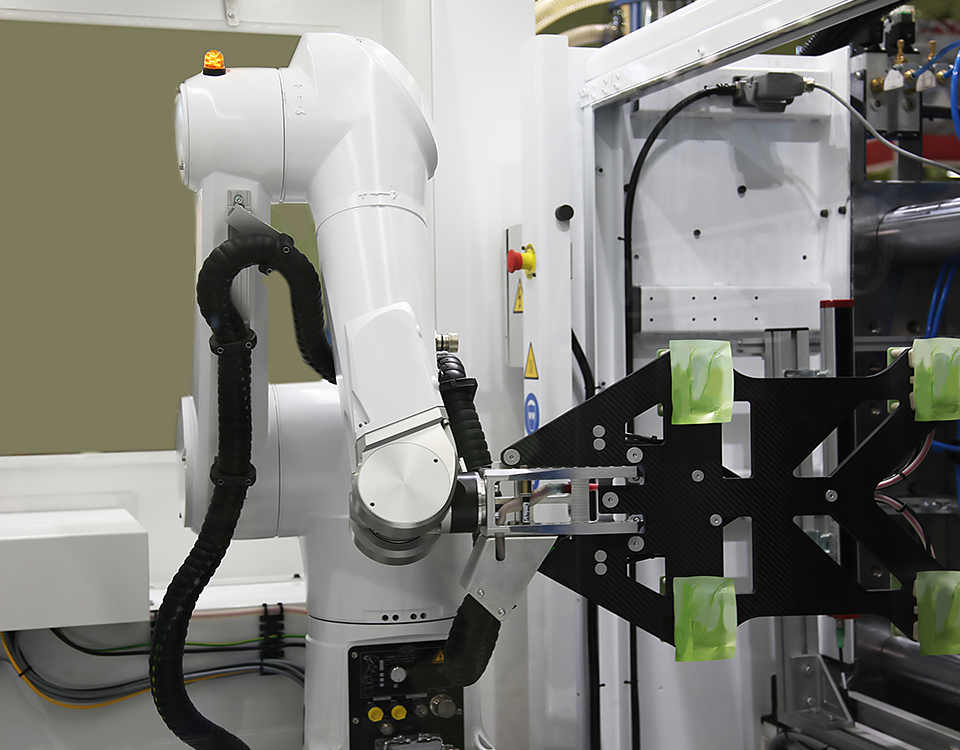

With this electrification, parts are expected to maintain high reliability even under unprecedented harsh working conditions. High-load capacity products are important parts that are indispensable to mechanical drive parts (injection shaft, mold clamping shaft, ejector shaft, extrusion shaft, plasticizing part).

Other products used in injection molding machines include "high-load drive dedicated ball screws" that have greatly improved load resistance by optimizing the circulation path configuration to maximize the ball diameter and designing dedicated high-load ball grooves, "thrust angular contact ball bearings" that achieve high load capacity by using large-diameter balls supporting dedicated high-load drive ball screws, and "needle guides" that have high load capacity, high rigidity, and are environmentally friendly.

As a comprehensive manufacturer that can develop and provide a full range of mechanical components, we will strive to contribute to the future development of injection molding machines.