Welcome to visit Fugui International Trade (jinan) Co., Ltd.website !

Belonging column:NACHI bearing

Email:admin@tytsbearings.com

Contact address:CN,Shandong,Jinan,Room 1501, Building A, Block C-1, Greenland Central Plaza

Whatsapp: +8618063525008

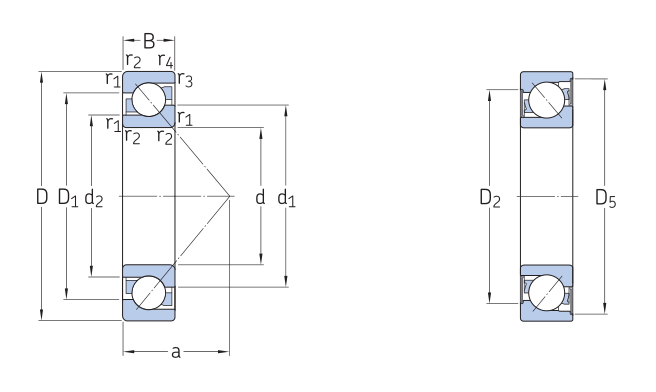

NACHI angular contact ball bearings can withstand both radial and axial loads simultaneously. The higher the speed and contact angle, the higher the axial load capacity.

A single row bearing can only withstand axial loads in one direction, and when subjected to radial loads, it will cause additional axial forces. And it can only limit the axial displacement of the shaft or housing in one direction.

If NACHI angular contact bearings are installed in pairs, the outer rings of a pair of bearings are opposite, that is, the wide end faces are opposite to the wide end faces, and the narrow end faces are opposite to the narrow end faces. This can avoid causing additional axial forces and limit the shaft or housing within the axial clearance range in both directions.

Secondly, there are three nominal contact angles: 15 °, 25 °, and 40 °. The larger the NACHI contact angle, the higher the axial load-bearing capacity. High precision and high-speed bearings typically have a contact angle of 15 °, which increases under axial force. Currently, there are over 70 variations of angular contact ball bearings.

Generally, the inner or outer ring has a locking port, and the inner and outer rings cannot be separated. After the outer ring is heated and expanded, it is assembled with the inner ring, rolling elements, and cage components. More balls are loaded than deep groove ball bearings, with a higher rated load in ball bearings, stronger rigidity, and smooth operation. The radial clearance can be adjusted by the mutual displacement between the inner and outer rings. Regularly use and apply preload to improve the rigidity of NACHI bearings.