Welcome to visit Fugui International Trade (jinan) Co., Ltd.website !

Belonging column:KOYO bearing

Email:admin@tytsbearings.com

Contact address:CN,Shandong,Jinan,Room 1501, Building A, Block C-1, Greenland Central Plaza

Whatsapp: +8618063525008

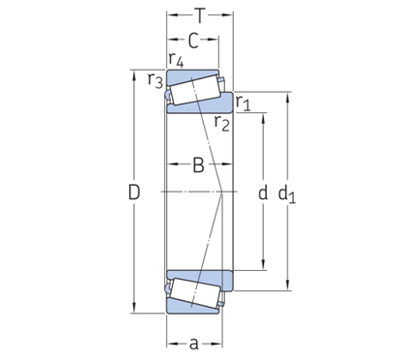

Conical roller bearings are mainly used to withstand combined radial and axial loads, mainly radial loads. Compared with angular contact ball bearings, it has a higher load-bearing capacity and lower limit speed. Conical roller bearings can withstand axial loads in one direction and limit axial displacement of the shaft or housing in one direction.

A single row tapered roller bearing has an outer ring, and its inner ring and a set of tapered rollers are enclosed by a basket shaped cage to form an inner ring component. The outer ring can be separated from the inner ring component. According to the ISO standard for the external dimensions of tapered roller bearings, any standard model of tapered roller bearing outer ring or inner ring component should be able to achieve international interchangeability with the same model of outer ring or inner ring component.

Usually, the cone angle of the outer raceway of a single row tapered roller bearing is between 10 ° and 19 °, which can simultaneously withstand the combined action of axial and radial loads. The larger the cone angle, the greater the ability to withstand axial loads. The bearing with a large cone angle, with the suffix B, has a cone angle between 25 ° and 29 °, and can withstand large axial loads. In addition, the clearance of single row tapered roller bearings can be adjusted during installation.

The outer ring (or inner ring) of a double row tapered roller bearing is a whole. The small end faces of two inner (or outer) rings are similar, with a spacer in the middle. The clearance is adjusted by the thickness of the spacer, or the pre interference of the double row tapered roller bearing can be adjusted by the thickness of the spacer.