Welcome to visit Fugui International Trade (jinan) Co., Ltd.website !

Belonging column:KOYO bearing

Email:admin@tytsbearings.com

Contact address:CN,Shandong,Jinan,Room 1501, Building A, Block C-1, Greenland Central Plaza

Whatsapp: +8618063525008

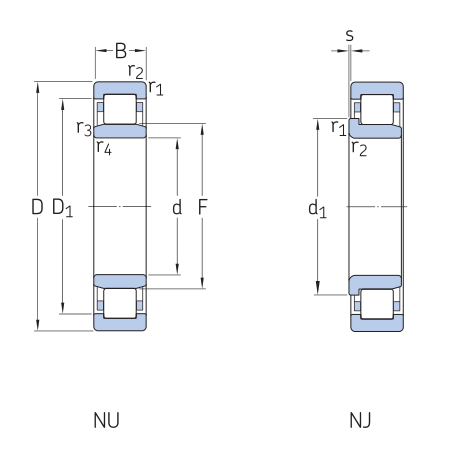

The friction between the rolling element and the sleeve edge is small, suitable for high-speed rotation. According to the presence or absence of retaining edges in the ring, there are single row cylindrical roller bearings such as NU, NJ, NUP, N, NF, as well as double row cylindrical roller bearings such as NNU and NN. This bearing is a separable structure with inner and outer rings. Cylindrical roller bearings with inner or outer rings without retaining edges, whose inner and outer rings can move relative to each other in the axial direction, can be used as free end bearings. A cylindrical roller bearing with double flanges on one side of the inner and outer rings and a single flange on the other side of the ring can withstand a certain degree of axial load in one direction. Generally, steel plate stamping retaining frames or copper alloy solid retaining frames are used. But there are also some that use polyamide formed retaining frames.

Characteristics of cylindrical roller bearings: The rollers are in line contact with the raceway or repaired to be in line contact, with a large radial bearing capacity, suitable for bearing heavy loads and impact loads; Low friction coefficient, suitable for high speed, with a maximum speed close to deep groove ball bearings; N-type and NU types can move axially and adapt to changes in the relative position between the shaft and the housing caused by thermal expansion or installation errors. They can be used as free end supports; The machining requirements for shafts or seat holes are high, and the relative deviation of the outer ring axis after bearing installation should be strictly controlled to avoid contact stress concentration; The inner or outer ring can be separated for easy installation and disassembly.

The cylindrical roller is in linear contact with the raceway and has a high radial load capacity. Suitable for withstanding heavy loads and impact loads, as well as high-speed rotation. The raceway and rolling elements of cylindrical roller bearings have geometric shapes. After improved design, the new structural design of the retaining edge and roller end face not only enhances the axial load-bearing capacity of the bearing, but also improves the lubrication conditions in the contact area between the roller end face and the retaining edge, thereby improving the performance of the bearing.