Welcome to visit Fugui International Trade (jinan) Co., Ltd.website !

Belonging column:KOYO bearing

Email:admin@tytsbearings.com

Contact address:CN,Shandong,Jinan,Room 1501, Building A, Block C-1, Greenland Central Plaza

Whatsapp: +8618063525008

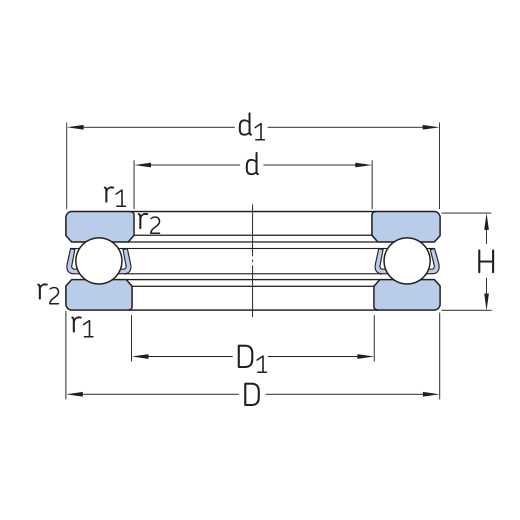

The thrust ball bearing adopts a design that can withstand thrust loads during high-speed operation, and is composed of a washer shaped ring with a rolling groove for the ball. Due to the cushion shaped ring, thrust ball bearings are divided into two types: flat bottomed cushion type and self-aligning spherical cushion type. In addition, this type of bearing can withstand axial loads, but cannot withstand radial loads.

Divided into unidirectional thrust ball bearings and bidirectional thrust ball bearings according to the force situation. Unidirectional thrust ball bearings can withstand unidirectional axial loads, while bidirectional thrust ball bearings can withstand bidirectional axial loads, where the shaft ring is matched with the shaft. The installation surface of the seat ring is a spherical bearing with self-aligning performance, which can reduce the impact of installation errors. Thrust ball bearings cannot withstand radial loads and have a lower limit speed.

characteristic

1. There are two types available: one-way and two-way

2. In order to allow for installation errors, whether it is unidirectional or bidirectional, spherical seat cushion type or ball seat ring type can be selected.

3. High quality steel - using ultra clean steel that can extend the life of bearings by 80%

4. Advanced grease technology - can extend the life of grease and improve the performance of bearings

5. High grade steel balls - quiet and smooth when rotating at high speeds

6. By using the collar in the option, installation errors are allowed.

Thrust ball bearings are only suitable for components that can withstand axial loads on one side and have low rotational speeds, such as crane hooks, vertical water pumps, vertical centrifuges, jacks, low-speed reducers, etc. The shaft ring, seat ring, and rolling element of the bearing are separate and can be installed and removed separately